Transformers are essential components of power systems and take a leading role in voltage regulation and energy distribution. There are two main types of transformers: oil-immersed transformers and dry-type transformers. They each look and apply differently and use other characteristics and advantages.

Construction and Design

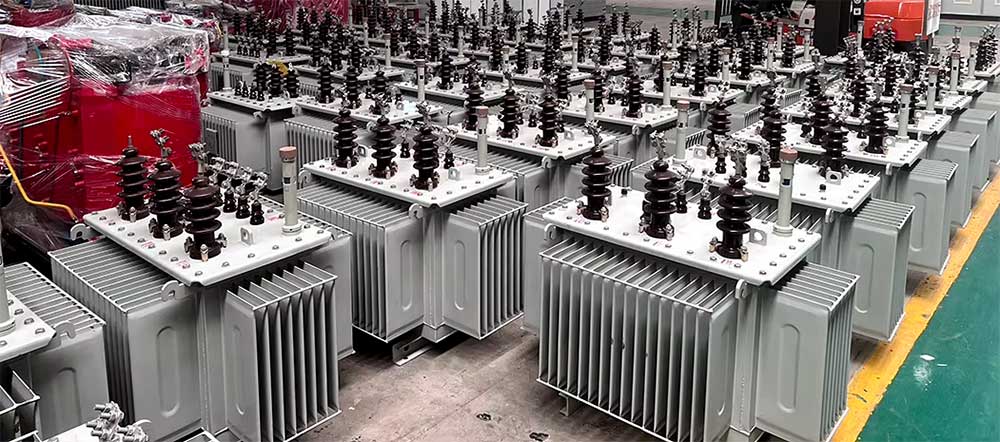

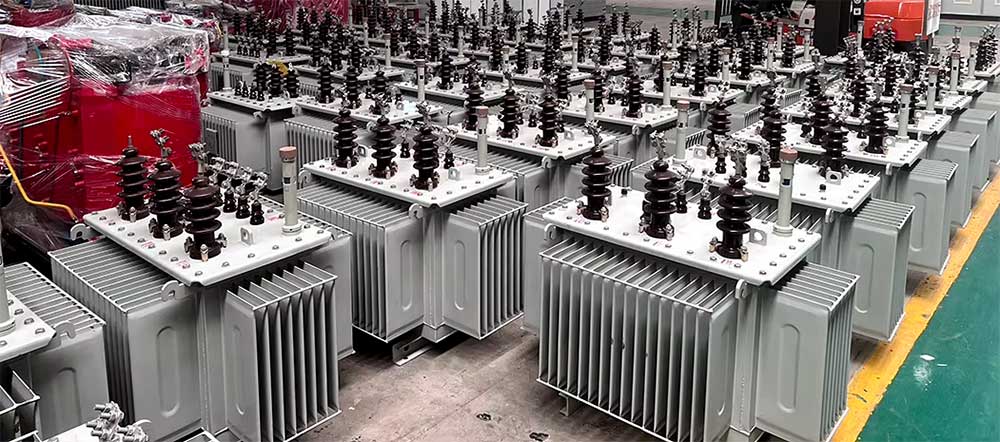

Oil-immersed Transformers

Also known as oil-filled transformers, oil-immersed transformers use insulating oil as a coolant and electrical insulator. The design uses an oil-filled, metal tank surrounding the core and windings. It’s the oil to dissipate heat generated during operation keeping things in optimum operation under heavy loads. Steel is the material from where the tank is made, and it can carry high voltages and environmental conditions.

Dry-Type Transformers

However, dry-type transformers make use of an insulating medium other than oil. They instead depend on air or solid insulation materials like epoxy or resin as electric insulation and cooling. This design decreases the risk of leakage and the elimination of a cooling system makes it more suitable for indoor applications. Dry-type transformers are lighter and more compact than oil-immersed transformers, allowing them to occupy less space, and hence making them easy to install in a space-constraining environment.

Cooling Mechanism

Oil-Immersed Transformers

Oil-immersed transformers are very effective because of oil’s ability to absorb and dissipate heat. Within the tank the oil circulates, and the heat is transferred away from the windings and core to keep the tank at an optimal operating temperature. Because it allows for much higher power loads, oil-immersed transformers do not overheat as easily and are therefore suitable for those extreme power requirements found in utility and industrial settings.

Dry-Type Transformers

Natural air convection, forced air cooling, or some combination thereof are used to dissipate dry-type transformer heat. They can be designed to handle relatively small power loads, but are not as thermally efficient as the oil-immersed transformer. In high-demand applications, therefore, dry-type transformers often need bigger enclosures or even cooling systems (fans, air conditioners), in order not to overheat.

Safety benefits as well as environmental implications.

Oil-Immersed Transformers

Oil-immersed transformers are effective in terms of cooling and insulation but offer some hazards to safety. Insulating oil presents a risk of any leak or spill into the environment and therefore must be managed to prevent this event. The oil can also degrade if not kept; if so, it could lead to electrical failures or fires. To prevent unscheduled stoppages of oil-immersed transformers safe operation requires regular maintenance, oil quality checks, and leak detection.

Dry-Type Transformers

Dry-type transformers are not included in oil and are considered safer and more friendly to the environment. Because they are not at risk of leaks or spills, they are well suited for sensitive environments such as schools, hospitals, and commercial buildings. In addition, the solid insulation materials used in dry-type transformers are normally non-toxic and have less environmental effect, so they become attractive in urban areas and areas with stringent environmental control.

Maintenance Requirements

Oil-Immersed Transformers

Regular maintenance is needed for oil-immersed transformers, to keep them reliable and long-lasting. Some of these include checking for oil, checking for leaks, and checking the cooling system. Regular maintenance allows you to detect potential problems before they become major problems, so they don’t cost you downtime and repair costs. Also, because of oil transformers need to replace oil at regular intervals to maintain their insulation properties.

Dry-Type Transformers

This means that dry transformers are normally low maintenance compared with oil transformers. But their solid insulation materials don’t degrade the way oil does, so they do not need to be inspected and replaced as often. Though, however, the cooling system requires regular inspections to make sure it’s working effectively, especially in high ambient temperatures environments.

Applications

Oil Transformers

In high-voltage applications such as power generation, transmission, and distribution systems, oil transformers are usually used. For utility substations and other industrial settings where lots of power needs to be converted and distributed conveniently, these are ideal. For outdoor installations, they’re great because of their ability to take heavy loads and temperatures.

Dry Transformers

Commercial and residential settings with limited space, and high safety are common places where dry transformers are used. They are commonly seen in cities, schools, hospitals, and data centers. Because they are of small size and are at low risk for environmental contamination, they are therefore well suited for indoor use. For safety reasons, some transformers may not have oil-immersed transformation.

Cost Considerations

Oil-immersed Transformers

The initial cost of oil-immersed transformers may be higher as they have to have structural materials necessary for structure and cooling system requirements. However, their durability and capacity to operate with high power loads can reduce long-term operating costs, particularly in high-demand applications. The life of an oil-immersed transformer can also offset the cost involved in the original investment.

Dry Transformers

In general, dry transformers are less expensive up-front and to install. In the long run, they can save costs with their simple design and lower maintenance requirements. Nevertheless, dry transformers will have higher operating costs for applications that need higher power handling and higher thermal efficiency than wet transformers, particularly in the presence of additional cooling systems.

What is the difference between oil transformer and dry transformer?

Both oil-immersed and dry-type transformers have an important role in power systems, and each has unique advantages and also can be applied. In high voltage and heavy load environments, oil-immersed transformers have good cooling and insulation while dry-type transformers are more applicable to indoor use where safety and environmental perspectives are more important. To know which of the two transformer types is the right solution for a particular application, one has to know the differences between these two transformer types.

If you have different opinions or want to know more, please leave a message on the website or contact us directly at info@wishpower.net