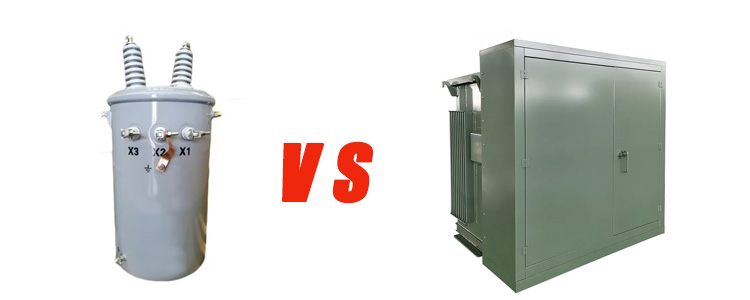

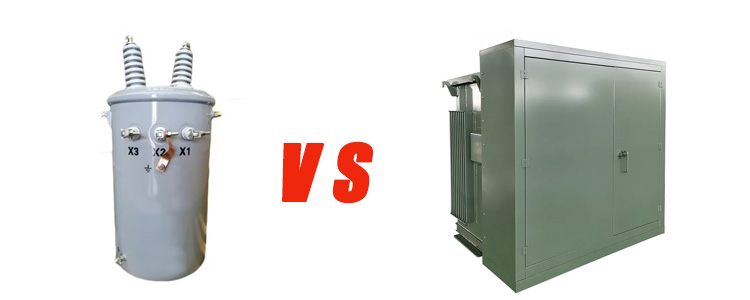

What is the difference between pole-mounted and pad-mounted transformers?

Transformers are electrical distribution systems played a key role as their primary function is to increase or decrease voltage levels for easy and secure power transfer. There are many types used, though pole-mounted transformers and pad-mounted transformers are used most frequently. Both have different designs, and installation applications, but serve the purpose of voltage transformation.

Pole-Mounted Transformers:

Design and Structure

Compact units and pole-mounted transformers are installed on utility poles, mostly in overhead distribution systems. The Ends are cylindrical or rectangular and have a strong, weatherproof outer shell to protect against environmental factors like rain, wind, and cold, and hot temperatures. Usually, these transformers are oil-filled with insulating fluids for cooling and insulation. Being lightweight and space-saving, this design is extremely suitable for regions with less ground space or highly populated areas.

Applications and Use Cases

Rural Electrification: Their power is used to serve sparsely populated areas where an overhead line is a more economical option.

Residential Areas: Low voltage power for households is supplied by these transformers which step down high voltage from the transmission lines.

Small Commercial Loads: Additionally, they also support small businesses or facilities with small energy requirements.

Advantages

Cost-Effective Installation: They are less land and installation cost-intensive because they are mounted on poles.

Easier Maintenance: With their location elevated, and in place for utility workers to use bucket trucks to make repairs, the time and effort of fixing are cut drastically.

Space Efficiency: This is highly valuable ground space-saving, so these are excellent for a narrow street or populated neighborhood.

Pad-Mounted Transformers:

Design and Structure

They are in contrast to pad-mounted transformers which are placed on concrete pads at ground level. Designed for safety, and able to withstand environmental exposure, all these transformers are enclosed in sturdy, tamper-proof metal housings. Cooling is usually accomplished by oil filling but the seals prevent leakage and contamination.

Applications and Use Cases

Underground Distribution Systems: Occurs in suburban or urban areas where lines must be buried for safety and taste.

Commercial and Industrial Facilities: They are high-load handles transformers used by factories, shopping malls, and large office complexes.

Substations: They play an important role in converting voltage levels in distribution substations.

Advantages

Safety: Pad-mounted transformers designed with tamper-resistant enclosures can be installed in public spaces and areas visited by children.

High Capacity: Because of this, pole-mounted units are suitable for heavy power requirements but incapable of handling larger loads.

Aesthetic Appeal: Pad-mounted transformers allow underground distribution of power, keeping them in clean and unobstructed landscapes.

Pole Mounted vs Pad Mounted Transformers

- Installation Location

Utility poles support pole-mounted transformers and are part of overhead distribution systems. Ground-mounted concrete pads typically used in underground systems, are referred to as ground-mounted transformers, also known as pad-mounted transformers.

- Power Distribution

When used in medium to low voltages for applications including residential areas and small businesses, pole-mounted transformers are best. The pad-mounted transformers are suited for better commercial and industrial use over higher loads.

- Aesthetic Considerations

In urban and suburban settings, pad-mounted transformers are often used because they can support areas underground power lines thus maintaining the area’s esthetic appeal. Despite being more visible, pole-mounted transformers are feasible for low-cost and efficient rural electrification.

- Safety Features

Enclosure on the pad-mounted transformers reduces the risk of accidental contact or vandalism because they are located within locked, tamper-proof housings. While elevated, pole-mounted transformers use their height for safety and have no such enclosures.

- Maintenance and Accessibility

So the pole-mounted transformers should be maintained by equipment under the name bucket trucks. However, pad-mounted transformers are easy to get to ground level for inspection and repairs.

What is the difference between pole-mounted and pad-mounted transformers?

Modern power distribution systems feature indispensable roles of both pole-mounted and pad-mounted transformers. In the context of cost-effective rural electrification and small-scale power delivery, pole-mounted transformers are the choice while pad-mounted transformers are a more robust solution for high-demand, urban and industrial situations. Factors such as power requirements, intended installation location, and specific safety or aesthetic needs will determine the type that is chosen. This insight enables utilities, and engineers to determine how to optimize power delivery and system efficiency by understanding the differences.

If you have different opinions or want to know more, please leave a message on the website or contact us directly at info@wishpower.net